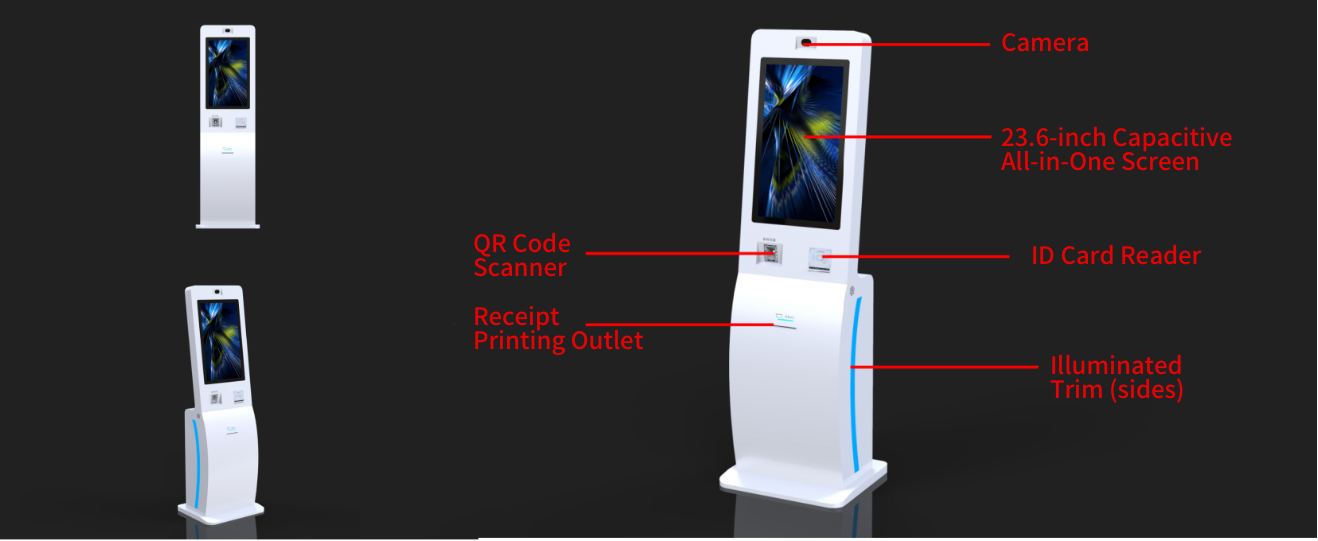

The Yibu All-In-One Machine integrates a camera, touch screen, IC identification, identity card recognition, barcode scanning, and receipt printing modules. It is designed to be used throughout the entire production line, in conjunction with the quick response center, for manufacturing monitoring and attendance punching in actual scenarios, thereby helping customers to upgrade their industry to digital.

Used to capture on-site images and videos. It can monitor and record the situation of workshops, event sites, and other places in real-time. By monitoring the activity in the area through a real-time video stream, it provides safety warning and surveillance functions. In the event of abnormal behavior or intrusion, the system will automatically trigger an alarm and store related video records for subsequent analysis and investigation. Used for quality control in the production process.

Adopts advanced touch technology and is equipped with a high-sensitivity touch screen. Users can interact directly with the screen using their fingers or a dedicated stylus. The touch screen, in conjunction with the all-in-one machine's software, provides an intuitive user interface. Through the touch screen, users can easily perform actions such as clicking, swiping, and zooming to browse menus, open applications, and enter text. This intuitive method of operation saves time and effort, enhancing the user experience. In scenarios such as workshop attendance, working hours reporting, warehouse in and out, and customer check-in at event sites, it can directly enhance the customer experience.

The IC card reader module is a device capable of reading and interpreting information on employee cards. It transfers data stored on IC cards to the system for processing, either through physical contact or contactless communication with the employee cards. The IC card reader module can be used for identification and verification of employee cards.

By reading the unique identifier (such as the card number) on employee cards, the system can quickly and accurately identify employee identities and verify them against a database. This facilitates functions like access control and attendance timekeeping, ensuring that only authorized employees can obtain corresponding permissions. Linked with access control systems, time attendance machines, or vending machines, it enables automated operations in various application scenarios. It can be used for workshop attendance timekeeping, stocking and unstocking in logistics warehouses, and recording logistics shipping operations. The data is retained for later traceability.

Combined with the Universal Code, workshop QR code, and traceability code, by scanning the QR code or barcode on goods, data can be traced, including supplier data, production line data, order data, etc. Also, you can pinpoint the designated warehouse location, shelf number, and so on for unidentified goods by scanning the code. In the context of events, scanning the event QR code or invitation code through WeChat can yield detailed information about the participants.

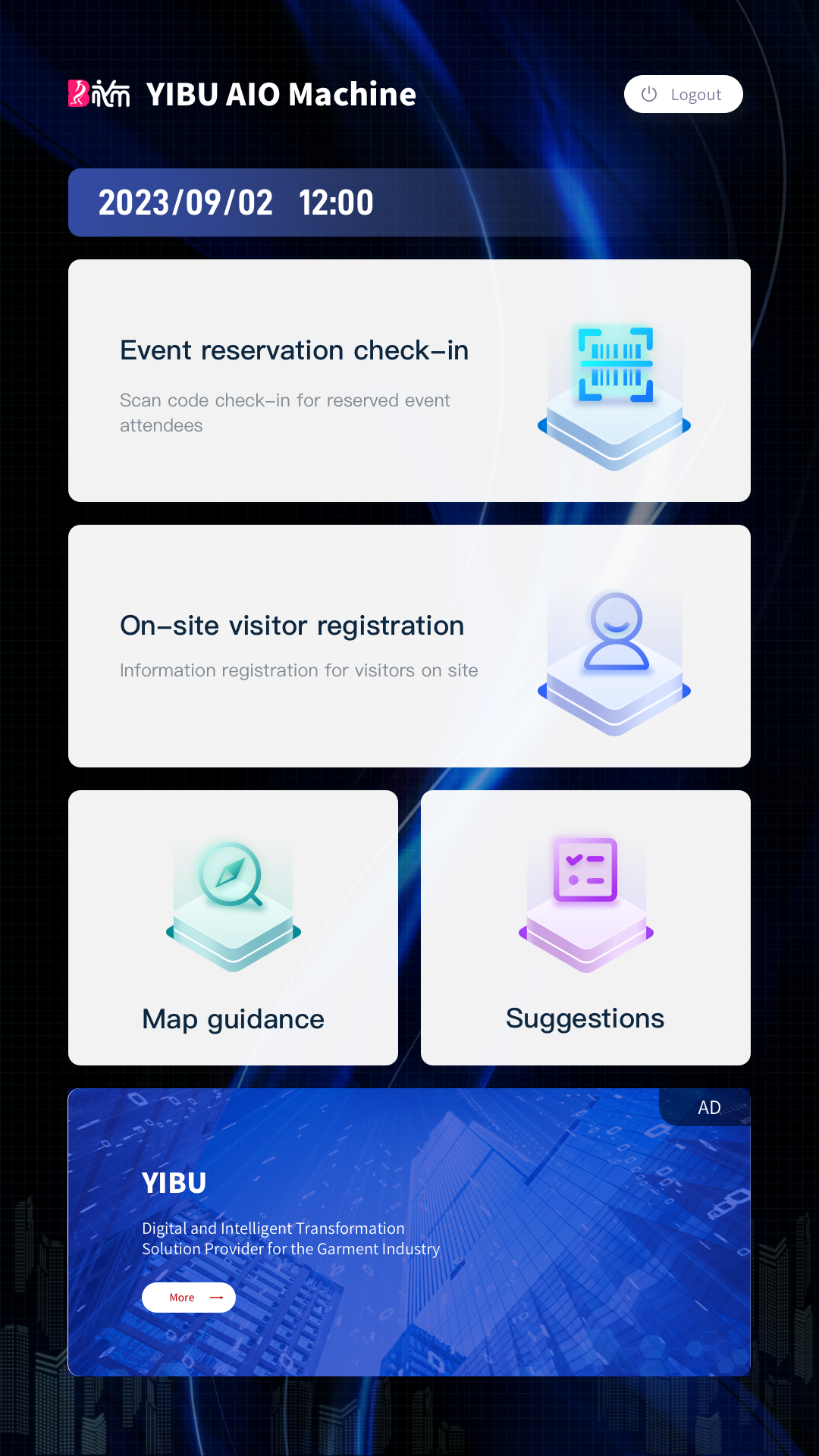

Event appointment and check-in; on-site visitor registration; map-based activity guidance; feedback and suggestions for the event; advertisement banner placement.

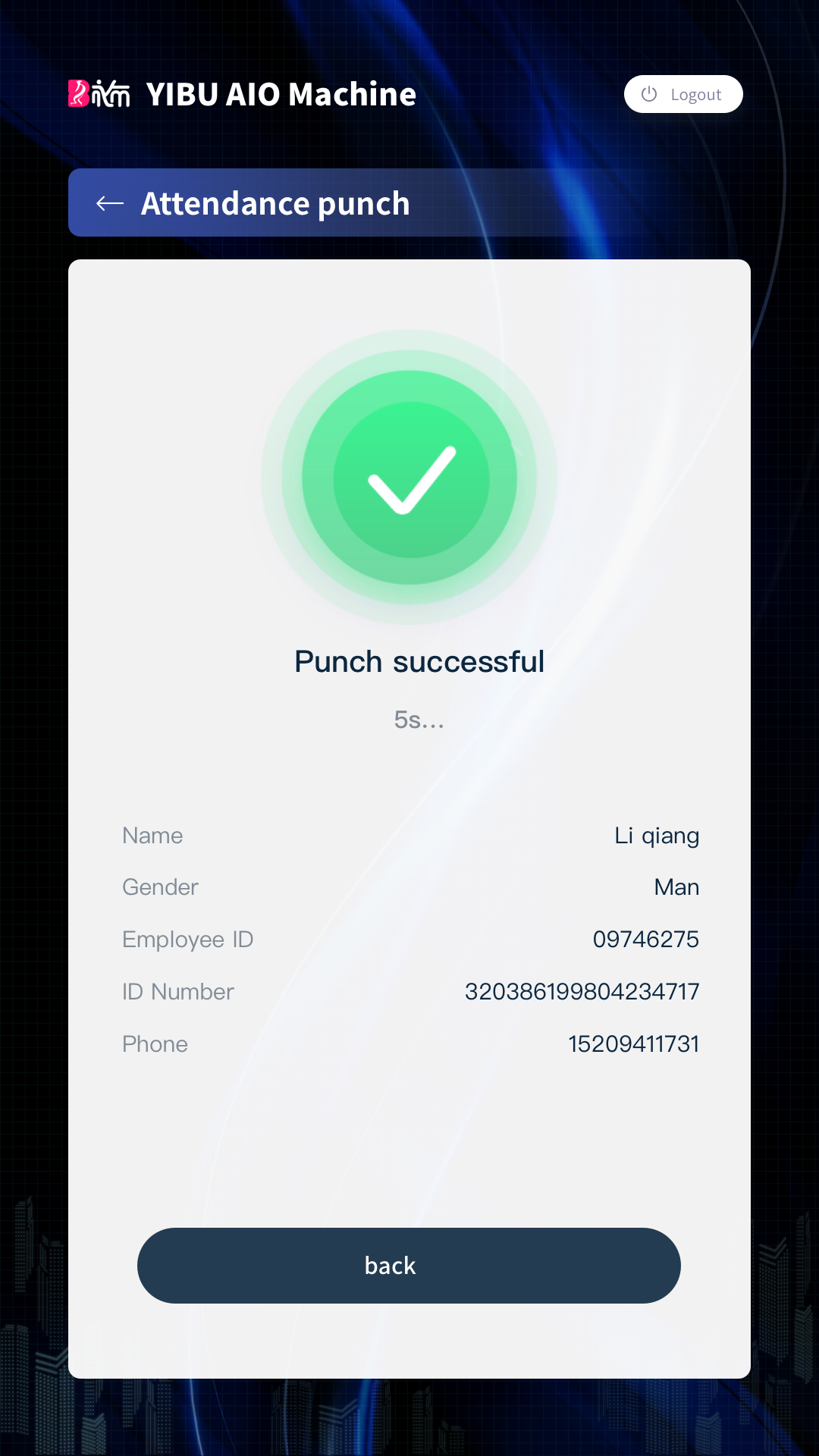

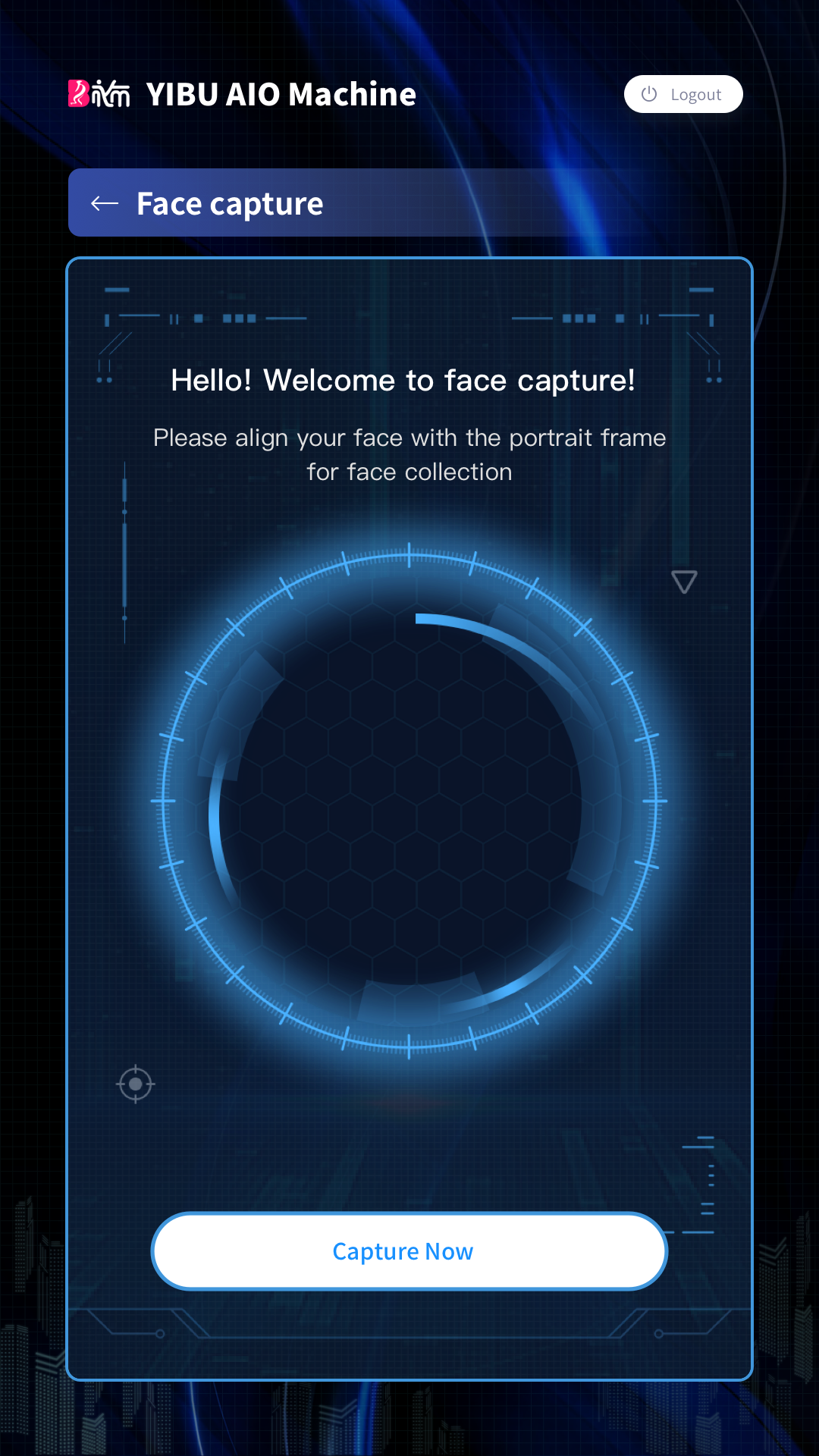

Workshop announcements; attendance timekeeping; facial data collection; employee card issuance; production reporting; workshop stock in and stock out registration, etc.